单发黑工艺流程示意图:  |

English is introduced

Ⅱ

1.Steel nigrescence agent is condensed Stir and make 10& nigrescence agent fully mixed with 90% water before it becomes workable lotion.

2.Heat the stainless parts to 200-560℃ and it turns to black as soon as it is dipped into mixture of nigrescence lotion.

3.Package and oil the parts after they are dried with the heat of 120-180 ℃ out of the lotion.

4.Keep the nigrescence agent at the temperature of 40-60℃.It will pollute the transmission devices if overheated.

5.Add nigrescence agent according to output.

The GOLDEN TIGER steel nigrescent agent takes utilizes the waste heat of workpiece tempering to generate black protective film of high molecular material according to thermal polymerization reaction mechanism to serve as a way of rust and corrosion prevention.It provides the environment-protective,energy-saving and high efficiency technical process and produces good color and luster and film with high light shade,thus is a good substitute for the traditional alkaline nigrescent agent.

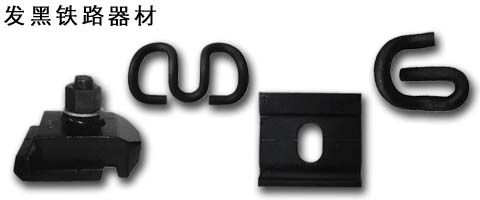

Steel nigrescent agent can be used in iron casting ,various mechanical parts and components made of materials such as carbon steel ,alloy steel and metal ceramic and is widely applicable in steel part industry including standard component , chain,spring and railway equipment .

Ⅰ Virtue and advantage of the product

1、Sort of Soluble emulsifier ,therefore environment-protective and safe;

2、The production goes on with heat-treating guipure furnace ,thus forming a highly efficient and economic production network.;

3、After nigrescent treatment ,the workpieces takes on good luser and carries strong performance of anticorrosion and rust protection.

4、If reduces labour intensity and improves invironment;

5、Acid picking is not needed before the nigrescent treatment while hydropeening can be omitted arter that ;no emission of waste water ,gas and industrial residue;

No hydrogen embrittlement on the nigrescent-treated workpieces.

1、Sort of Soluble emulsifier ,therefore environment-protective and safe;

2、The production goes on with heat-treating guipure furnace ,thus forming a highly efficient and economic production network.;

3、After nigrescent treatment ,the workpieces takes on good luser and carries strong performance of anticorrosion and rust protection.

4、If reduces labour intensity and improves invironment;

5、Acid picking is not needed before the nigrescent treatment while hydropeening can be omitted arter that ;no emission of waste water ,gas and industrial residue;

No hydrogen embrittlement on the nigrescent-treated workpieces.

Ⅱ

1.Steel nigrescence agent is condensed Stir and make 10& nigrescence agent fully mixed with 90% water before it becomes workable lotion.

2.Heat the stainless parts to 200-560℃ and it turns to black as soon as it is dipped into mixture of nigrescence lotion.

3.Package and oil the parts after they are dried with the heat of 120-180 ℃ out of the lotion.

4.Keep the nigrescence agent at the temperature of 40-60℃.It will pollute the transmission devices if overheated.

5.Add nigrescence agent according to output.

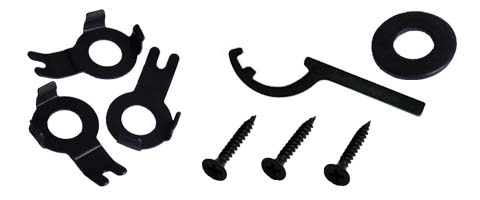

常用于发黑的工件类型:

发黑弹簧件